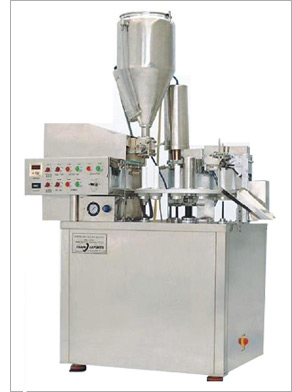

SATF is designed to fill and seal aluminium / plastic / lami tubes. The machine is suitable mainly for pharmaceutical, cosmetic and food industry. Machine can be used for filling of cream, ointment, gel, paste, balm and other similar viscous products by means of a volumetric dosing system.

Machine available in two configurations:

| Operation System | Single Head, Rotary Index Table |

| Output | up to 1800 tubes per hour for alu tubes / 2400 tubes per hour for lami and plastic tubes |

| Product Handled | Cream, ointment, gel, paste, balm and other similar viscous products. |

| Tube Diameter | Minimum 12 mm to maximum 50 mm |

| Tube Length | Minimum 50 mm to maximum 220 mm |

| Tube Loading | Manual |

| Tube Orientation | Manual |

| Product Hopper | S.S. 304, 50 liters capacity. {Water jacket with electrical heating and hot water circulation pump optional} |

| Product Agitator | Slow speed agitator for stirring of product in hopper as an option |

| Filling Nozzle | Fixed nozzle, with tube lifting at filling station – to lift up the tube so that nozzle gets inserted inside tube while filling. {Diving nozzle optional}. NO−TUBE−NO−FILL system incorporated. |

| Tail Cutting | By suck-back method (to prevent dripping after filling operation) |

| Dozing Range | a) 3 to 30 ml b) 30 to 100 ml c) 100 to 250 ml |

| Tube Sealing | By hot air tool for plastic and lami tubes By double fold and crimping tool for aluminium tubes |

| Batch Code Embossing | In crimping jaws for alu tubes In sealing jaws for plastic / lami tubes |

| Tube Ejection | Automatic, through a discharge chute for collection |