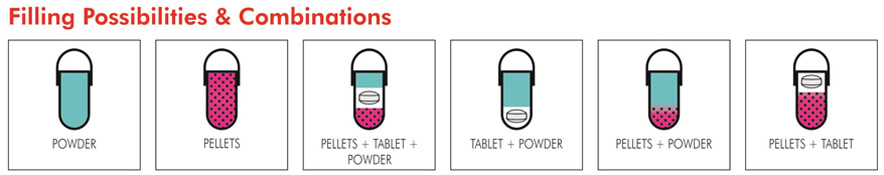

ENSULE is a Fully Automatic Capsule Filling machine to fill powder in the form of slug in hard gelatin capsules. These are high speed, high performance machines that incorporates latest international design and is built with precision using most appropriate materials and up-to-date manufacturing systems. Different models are available for various output requirements. This machine is also capable of filling pellets and tablets for flexibility of multiple dosage combination such as powder+pellets+tablet. It is an extremely durable and reliable machine that fills dosages to the highest accuracy and is capable of filling all sizes from #00 to #5 of capsules. It is also easy to clean and meets GMP standards.

| Model | ENSULE–750 | ENSULE–1500 | ENSULE–2000 |

| Rated Output (powder) | 45,000 per hour | 90,000 per hour | 120,000 per hour |

| Rated Output (pellets) | 35,000 per hour | 70,000 per hour | 95,000 per hour |

| Electrical Connection | 415 V, 3 Ph AC + N + Earth (other voltage on request) | ||

| Power Consumption (inclusive of drive, vacuum pump & ADU) | 6.5 kw | 8 kw | 8 kw |

Empty Capsule Loading And Separation Assembly

The function of Capsule Loader is to orient the empty capsules with “Cap up and body down” by rectifying mechanism and to load them into the upper segment of Turret. The vacuum under the lower segment separate the capsule body into the lower segment hole from the capsule cap. The capsule cap remains inside the upper segment.

The Turret has a rotating indexing motion. It has 10 pairs of cap and body holder segments with the cap holder segment located above the body holder segment. Main function of the turret is to transport Capsules from one station to another station. During the dwell period of indexing various operation related to capsule filling are performed. The operations are:Empty Capsules loading to the segment plate, opening of capsules, filling of powder, ejection of un-separated capsules, closing of capsule, discharge of filled capsules and segment cleaning. Fully enclosed structure protects the moving components from dust contamination.

Powder is supplied into the dosing chamber by the augur inside the powder hopper. The height of powder bed in powder tub is maintained by the powder sensor, which activates the augur inside the powder hopper when the level of powder lowers than desired level.

Powder is tamped into the dosing disc at five tamping stations and the formed slugs are transmitted into the capsule bodies positioned under the dosing disc by transfer pins at the sixth station.

Fill weight is adjusted by penetration of the tamping pin with the knob on the tamping pin holder.

Jicon Industries are leading Pharmaceutical Machines Manufacturers and Exporters in Nepal, Bangladesh, Sri Lanka, Philippines, Afghanistan, Iran, Iraq, Syria, Jordan, Turkey, Israel, United Arab Emirates, Saudi Arabia, Yemen, Egypt, Algeria, Sudan, Ethiopia, Kenya, Uganda, Tanzania, South Africa, Nigeria, Ghana, Russia, United States of America, El Salvador.

Dust collector unit or air displacement unit is used for removal of un-separated capsules and powder dust from the machine.

Flow : 2800LPM

Motor: 3.0 kw